see more about us

see more about us

Contact Us

Contact Us

182mm mono solar panel丨 full black 410W solar module Experience the next generation of solar technology with SpolarPV, where innovation meets sustainability for a brighter, greener future.

430W Full Black Solar Panel 丨N-type Cell Panel Choose SpolarPV for your solar solutions, where we blend innovation with sustainability, paving the way for a brighter and greener tomorrow.

Romania rooftop 550w solar panel丨High Conversion Efficiency panel丨solar energy solutions Step into a sustainable future with SpolarPV, your trusted partner for high-quality, innovative solar energy solutions.

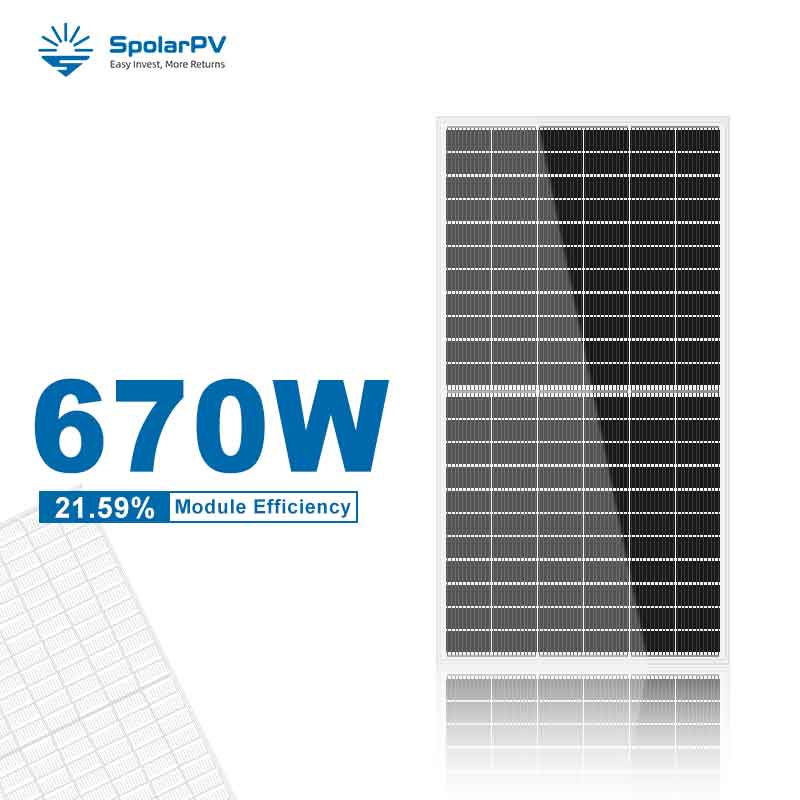

670w perc solar panel丨panel for ground solar systemStep into the world of SpolarPV, where technology and nature unite, offering you high-quality solar solutions designed for the modern world.

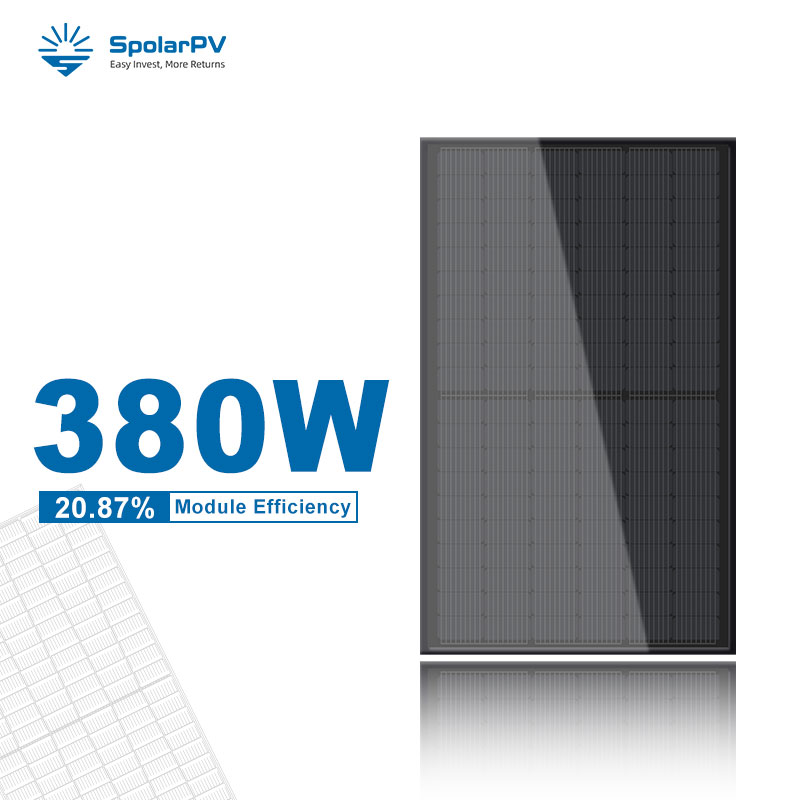

full black solar panel 380w丨166mm mono solar module Experience the next generation of solar technology with SpolarPV, where innovation meets sustainability for a brighter, greener future.

Ultra-High Efficiency Solar Module丨182mm Mono Perc Panel Harness the power of the sun like never before with SpolarPV's state-of-the-art solar solutions, designed for unparalleled efficiency and reliability.

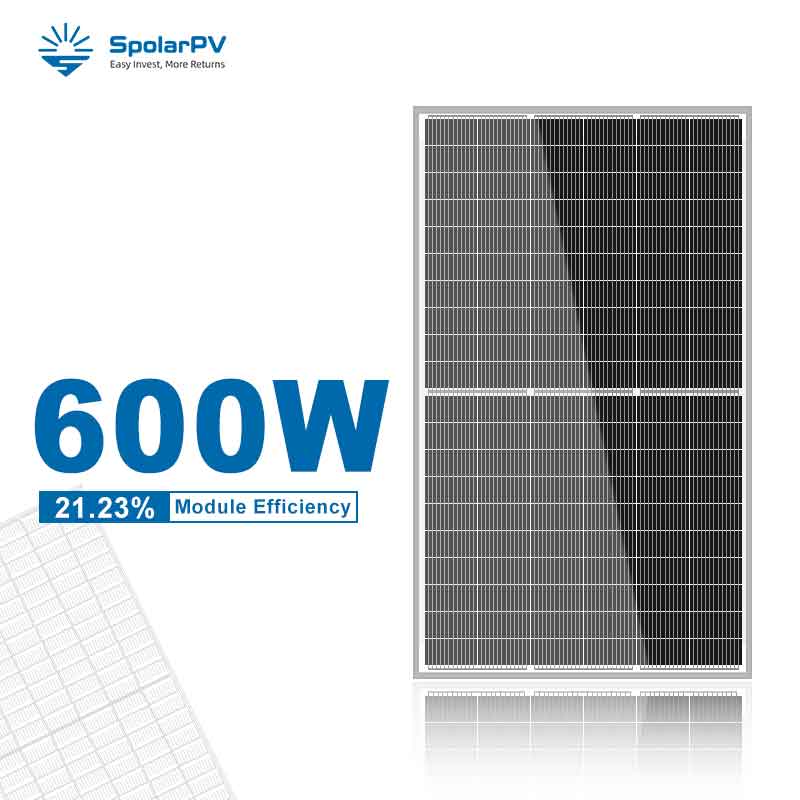

600w High Efficiency Panel丨Advanced Solar Energy SolutionsDiscover SpolarPV, where cutting-edge technology meets eco-friendly innovation, offering you the gateway to a sustainable and energy-efficient future.

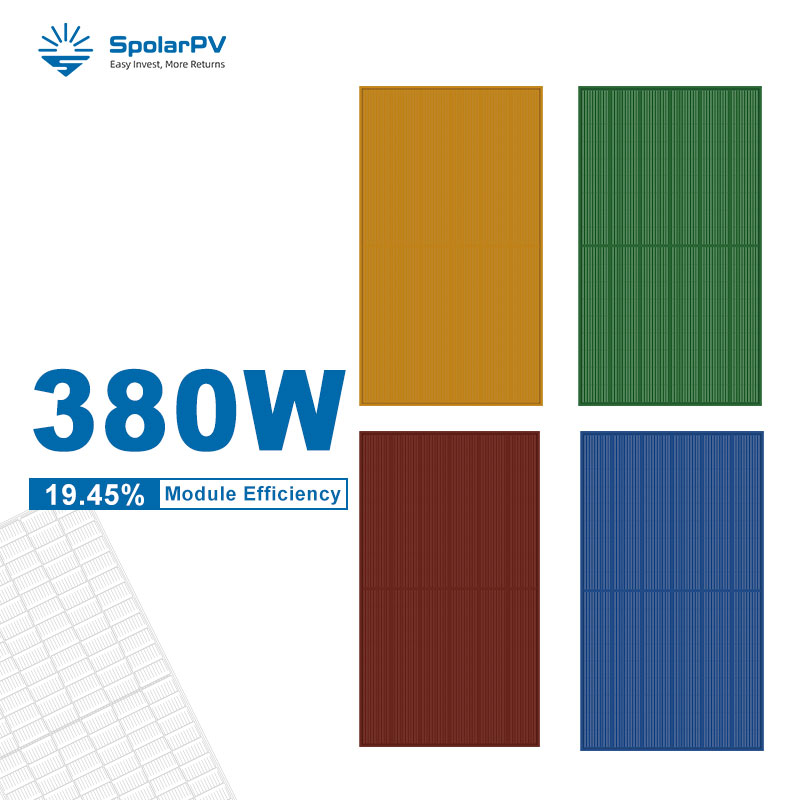

High-Efficiency BIPV Module丨Colorful Solar Tile Experience the beauty and efficiency of our BIPV solartile, a product that seamlessly integrates into building facades, offering not only a visually pleasing appearance but also a significant reduction in energy costs.

"Explore our showcase of innovative projects powered by SpolarPV's cutting-edge solar panels, exemplifying our commitment to a sustainable future."

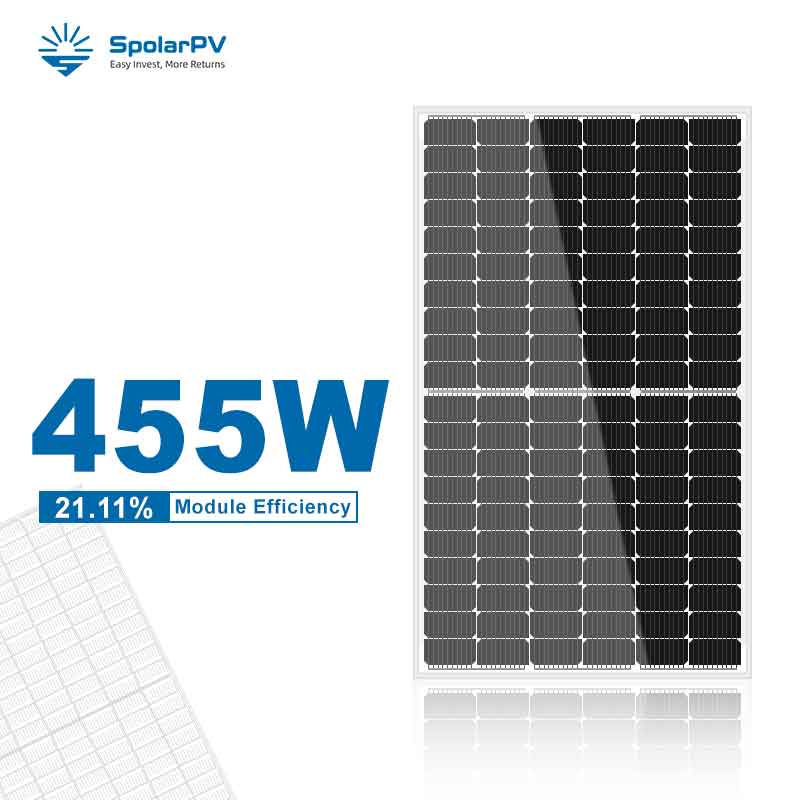

SpolarPV recently achieved success with the completion of a solar installation project in Strandvik, Norway, boasting a total capacity of 27.3KW. The project featured the use of 455W double-glass solar panels equipped with 120 pieces of 182mm solar cells, incorporating Perc technology for enhanced performance. Project Highlights: 1. Total Capacity: The 27.3KW solar system now provides a reliable source of clean energy for the Strandvik region, reducing dependence on traditional power sources. 2. Double-Glass Technology: Employing 455W double-glass solar panels, the project utilizes double-sided photovoltaic technology to maximize energy collection efficiency. 3. High Mechanical Load Capacity: SpolarPV's solar panels are designed to withstand high mechanical loads, ensuring outstanding performance even in adverse weather conditions. 4. Perc Technology: The utilization of 120 pieces of 182mm solar cells, incorporating Passivated Emitter Rear Cell (Perc) technology, enhances the overall efficiency of the solar panels. Customer Feedback: Post-project completion, the client expressed satisfaction with SpolarPV's excellent service and high-quality products. They emphasized the professional team's efficient communication and meticulous handling of technical details throughout the project execution. Conclusion: SpolarPV's success in the Strandvik project further solidifies the company's leading position in the solar industry. By providing efficient and reliable solar solutions, SpolarPV continues to earn the trust and commendation of clients in the renewable energy sector.

We're thrilled to share an impressive rooftop installation featuring our SpolarPV 410W full black solar panels in Aalborg, Denmark, thanks to a photo from one of our valued customers. This solar system boasts an impressive 8.2KW capacity and was installed in the year 2023. Located in Aalborg, Denmark, it's making waves for its high efficiency and outstanding reliability. The SpolarPV 410W full black solar panel is equipped with state-of-the-art PERC technology and features 182mm solar cells, totaling 108 cells in the module. This technology not only enhances the system's performance but also maximizes its efficiency, excelling in producing power from both sides (bifacial generation). With a conversion efficiency of 21.03%, you can be sure that you're harnessing every ray of sunshine. We have full confidence in the quality of our products, which is reflected in our warranty policies. This system comes with a generous 12-year product warranty and a 30-year linear performance warranty, ensuring your investment is safeguarded for the long term. This case study is a testament to SpolarPV's continued progress in the field of renewable energy and the immense potential of solar technology in reducing energy costs, carbon footprint, and enhancing energy independence. If you're interested in learning more about SpolarPV's products and services or want to explore our range of solar panels and solutions, please feel free to get in touch with us. We look forward to providing you with sustainable, efficient energy solutions to help you realize your vision of a green future.

Under the picturesque skyline of Viborg, Denmark, SpolarPV has brought forth a remarkable solar energy project, showcasing our advanced solar technology and exceptional performance. This case study features SpolarPV's 410W all-black modules equipped with 182mm solar cells and PERC technology, totaling 108 panels, boasting an impressive 21.03% module efficiency. Key Highlights: High Efficiency: SpolarPV's all-black modules are renowned for their outstanding performance, boasting an efficiency of up to 21.03%, ensuring maximum energy yield. Reliability: PERC technology (Passivated Emitter Rear Cell) enhances module reliability and stability, ensuring long-term consistent energy production. Environmental Sustainability: Harnessing solar energy reduces carbon emissions, contributing to climate change mitigation, a crucial step for our planet. Year 2023: This project represents SpolarPV's latest technology and innovation in the solar energy field, showcasing our leading position in the energy industry. Location: Viborg, Denmark: This project is situated in the beautiful city of Viborg, Denmark, providing the local community with clean, renewable energy. With a total installed capacity of 5.74 kW, this project generates a significant amount of electricity, reducing energy costs and dependency on traditional sources for the local community. We take pride in the success of this project, which not only demonstrates SpolarPV's excellence in technology but also contributes to the Viborg community's access to renewable energy. This case study showcases the feasibility and benefits of solar energy, inspiring more to adopt sustainable energy solutions. If you are interested in incorporating solar energy into your life or business, please reach out to us to learn how we can provide customized solar solutions for your needs. SpolarPV is dedicated to driving the growth of renewable energy, creating a cleaner, greener world for the future.

Project Details: Module: Monocrystalline Balcony Modules Acreage: 120 ㎡ Year: 2021 Location: Menzingen, Switzerland Project Overview: This case study presents the intriguing details of SpolarPV's innovative 120m² solar balcony, featuring advanced Monocrystalline Balcony Modules with a power rating of 280W. These modules are equipped with tempered glass for double-sided power generation. Let's delve into the various facets of this unique solar energy project. Project Background: Located in Menzingen, Switzerland, this project underscores the region's commitment to sustainable energy and forward-thinking design. SpolarPV selected this site to explore the potential of solar power in urban settings, utilizing balconies to contribute to the local energy needs while incorporating cutting-edge transparent solar technology. Module Selection: SpolarPV's choice of Monocrystalline Balcony Modules, enhanced with tempered glass for bifacial power generation and boasting a power rating of 280W, exemplifies the company's dedication to innovation and sustainability. These modules offer remarkable performance and the distinct capability to generate electricity from both sides, making them a pioneering choice for this solar installation. System Performance: Commissioned in 2021, the 120m² solar balcony quickly became an intriguing addition to urban energy solutions. Its bifacial power generation capability ensures efficient energy production, reducing dependence on conventional energy sources and contributing to a more sustainable urban environment in Menzingen. Achievements and Future Prospects: SpolarPV's solar balcony project in Menzingen serves as a remarkable example of integrating renewable energy into urban spaces. The company is committed to expanding such innovative initiatives, providing clean and creative power solutions in urban environments, and promoting the adoption of transparent solar technology for a more sustainable and eco-friendly urban future. In conclusion, SpolarPV's 120m² solar balcony, featuring Monocrystalline Balcony Modules with tempered glass and bifacial power generation capability, represents a significant advancement in the integration of solar energy into urban environments, offering a glimpse into a more sustainable and energy-efficient future for urban spaces in Menzingen, Switzerland, and beyond.

Dive into the latest updates and breakthroughs from SpolarPV, where our solar panel innovations light up the headlines

Founded in 2010, SpolarPV Technology Co., Ltd has been specialized in the design, manufacture and marketing of solar cells, solar modules, and solar power systems. The company, located in the capital city of Jiangsu Province, Nanjing, covering 6,000 m2, boasts advanced automatic ...

Benef. Bank China : Bank of Ningbo, Nanjing Branch

SWIFT BIC : BKNBCN2NNAN

Bank Add. : 19F, Plaza B, Bank of Ningbo Building, No.229 Jiangdong(M) Road, Jianye Distr. Nanjing China 210000

USD : 72122025000009289

EURO : 72125025000003031

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.